Open 6.54. The main advantages of the Cutting utility. Possibility of manual and automatic segmentation for large products

First I used Cutting 2, then Cutting 3. They differ quite a lot. But I liked the Cutting 2 version better. The third version has additional features, which according to by and large not really needed for small-scale production. Cutting 2 still helps me in preliminary calculation of the amount of material and the length of cutting lines for large orders, such as kitchens. To create the final cutting map, I use the Nowy Rozkrój program (Cut Optimiser or New Cut Manager) from the creators of the PRO100 program. . Both sites can be switched to Russian and read the description of the programs. Now I will describe the simple process of creating cutting cards. .

We open any project we created in PRO100. Click on the Σ tab.

The window that opens will display a table in which all elements of the project with their characteristics will be indicated. At the bottom of the window we find the Copy all tab.

Let's click on it. Now we can insert a table with our elements into the list of parts in Cutting 2. But we only need elements of the base material, let’s say laminated chipboard with a thickness of 18 mm. Therefore, open Excel and insert the list of PRO100 elements. Now we select those lines in which the elements are not 18 mm and delete them. As a result, what remains is a table consisting of 4 columns, in one of which there is only the number 18 in all cells. Select and delete this column. Select and copy the remaining elements. Launch the Cutting 2 program. Parts table on the right.

If it is not empty, click on the X icon above the right table and confirm clearing the list. Now click right key on the first empty cell of the list and in the drop-down menu select the line Add from clipboard.

Click on the Run calculation icon.

The cutting map is ready. Can be printed and used. But I encountered some inconveniences. For example, the numbers are too small, the cutting lines are not clear enough.

The people who cut the material for me were unhappy about having to use a magnifying glass. But for the preliminary calculation of the cost of the product, the program was ideal due to the transfer of parts from PRO100 to Cutting 2 described above.

The Nowy Rozkroj program is a better optimizer.

But all part dimensions must be entered manually.

The program calculates several cutting options at once.

Depending on what is important to you, you choose your option. The option with a shorter total length of cutting lines is more suitable for me, while others need an option with fewer scraps (junk).

First, in the settings, I specify the cutting option without stripes,

which allows you to place large quantity details. After the first cutting attempt I can see how much free space stays on last sheet. If more than 30% is not occupied by details, then in the program parameters I indicate the horizontal cutting option

and start the final calculation. The remaining horizontal stripe The seller keeps the popular colors of the material, which reduces the cost of the furniture. The cutting maps created by the Nowy Rozkroj program are quite detailed and clear, the dimensions are displayed perfectly.

The cutting result may be different. For example, you made the optimal cutting with the option without a strip, and you ended up with 3 sheets and 3 parts. This is especially important if the seller does not sell this color of material in stripes, but only in sheets. In this case, use the following option:

When adding each part, uncheck the Part Properties table in the Structure position.

Then, looking at your design, go through the detailing and note the structure in the details, the structure on which can only be consistent with the design, i.e. other structure options on these parts are not acceptable. If this method does not help, then reduce the size of hidden parts, such as plinths and connecting strips, by 10 mm or more. But don't overdo it.

There is another important advantage of this program. If you mark an edge on any side of the part, then it will not move from this side to the other when the part is rotated by the optimizer, which can happen in other programs. If the end edge is made of paper, the dimensions of the parts remain the same as in the project, but if the PVC edge is 1-2 mm thick, then do not forget to subtract the thickness of the edge from the size of the adjacent side with the one being pasted.

An example of drawing up cutting maps

Do not pay attention to the beginning of the video until the Nowy Rozkrój program starts. And then everything is on topic. A small technical hitch.

If your sheet, for example, is 2800 by 2070, and the side trim is 10 mm, forgetting that you need 4 mm for the cut, you indicate the part size 2790 by 600 with an edge of 2790. As a result, the edge slides by 600. Pay attention to this is attention. One day I didn’t check the card and gave it to work. Firstly, the guys had a hard time gluing the edge to the 600 side, because... the part rested on the workshop door, we had to move the machine. No one thought that a distance from the machine to the wall of 2.5 m could ever be insufficient. And secondly, I had to pay to have the edge glued on the long side, and at that moment I didn’t count on that. Therefore, be careful.

An error you may encounter when creating cutting plans

Cutting – cutting program sheet materials: particle board, glass, etc. The program for cutting chipboard allows you to reduce and optimize material consumption; it records waste, including “business” waste, which is not taken into account when calculating the cost of the order. The utility can be used in enterprises engaged in the mass production of cabinet furniture; for this purpose, the concept of ordering has been introduced into its functionality. All completed orders are automatically entered into the order database, and subsequently it is possible to repeat or change them. You can download Opening for free on this website.

To start working with the utility, you need to set the dimensions of the sheet and the parts that will be cut from it. Next, the program will independently select best option cutting with the least amount of waste. If necessary, you can use the material database available in the program, which contains standard sizes of sheets or rolls. In this case, it is enough to specify the material to be cut, and the utility will automatically calculate according to standard parameters leaf.

The cutting program works according to two main algorithms for optimizing chipboard consumption - reducing total waste and increasing continuous cutting. Reducing overall waste means cutting with a minimum amount of scraps. The continuous trim increase mode, in addition to reducing waste, is used to create a maximum trim that can then be used for another order. You can also save on material by combining two orders if they use the same material.

The main advantages of the Cutting utility

- Two cutting optimization algorithms.

- Database standard sizes sheets.

- Working with two types of edges.

- Works with both sheets and rolls.

- Database of completed orders.

During cutting, all cuts are made from one edge of the sheet to the other - either horizontally or vertically. The material consumed for cutting and other technological operations is taken into account when calculating cutting. The utility allows you to work with two types of edges. The program allows you to optimize the consumption of not only sheets, but also rolls. If necessary, it is possible to use Cutting in online mode.

You can cut sheet material manually, but it requires a lot of time and special skills. It is much easier to do this by using related programs. They will help optimize the cutting map, offer other layout options and allow you to edit it yourself. In this article, we have selected for you several representatives who do an excellent job.

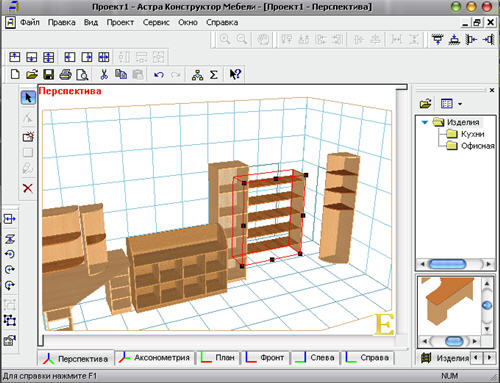

Astra Cutting allows you to work with orders by importing their blanks from the catalog. There are only a few templates in the trial version, but their list will expand after purchasing a program license. The user manually generates a sheet and adds details to the project, after which the software automatically creates an optimized cutting map. It opens in the editor, where it is available for editing.

Astra S-Nesting

The next representative differs from the previous one in that it offers only a basic set of functions and tools. In addition, you can only add pre-prepared parts of certain formats. The cutting map will appear only after purchase full version Astra S-Nesting. In addition, there are several types of reports that are generated automatically and can be printed immediately.

Plaz5

Plaz5 is outdated software and has not been supported by the developer for a long time, but this does not prevent it from performing its task efficiently. The program is quite easy to use and does not require any special knowledge or skills. The cutting map is created quite quickly, and the user only needs to specify the parameters of parts, sheets and design the map.

ORION

Last on our list is ORION. The program is implemented in the form of several tables into which you enter necessary information, and then the most optimized cutting map is created. From additional functions There is only the option to add an edge. ORION is distributed for a fee, and trial version available for download on the official website of the developers.

Cutting sheet material is a rather complex and time-consuming process, but this is if you do not use special software. Thanks to the programs that we reviewed in this article, the process of drawing up a cutting map will not take much time, and the user is required to make a minimal amount of effort.

If we talk about programs for sawing wood-based sheet material (chipboard), then there are many programs for cutting chipboard sheets, you can, for example, use "Pro100 cutting".

In the furniture business, the program for cutting chipboard sheets plays a rather important role, because the correct sawing of chipboard sheets is one of the most important qualities, in the manufacture of furniture.

Order cutting laminated chipboard now!...

Determining the quality of the cut is not difficult: if there are no chips on the workpieces, we can conclude that the cut was done properly. In the furniture business, much attention is paid to cutting sheet materials. Products made from particle boards do not look very good if there are saw marks on the visible side.

Today, in furniture workshops everything is automated to the maximum extent possible. For example, a number of machines are used in production that cope with this task quite successfully. These include equipment such as format cutting, filler and edge banding machines.

To quickly cut particle board, experts use a cutting program such as Pro100 cutting.

Note the sawing of particle board sheets on a Festool saw. If we take, say, laminated chipboard, then it is better to use a format cutting machine, since this machine is convenient for sawing laminated chipboard (you can cut up to a hundred sheets per day). Concerning pricing policy, then it depends on the company that offers this service.

You can also use a Festool plunge-cut saw to cut chipboard sheets. It is not a very expensive option. Due to the fact that the above-mentioned saw has a good price/quality ratio, this option is popular. There is also the following programs sawing chipboard, which are worth paying attention to.

Let's look at them in more detail:

"BASIS-RESCROY" are unique, modern programs, with visual and clear interface and has a powerful mathematical algorithm optimal cutting any materials used in furniture production. These Basis-Cutting programs are included in the Basis-Furniture Maker complex.

The following cutting program, which is also popular - CUTTING. It is designed to optimally cut the material into parts, depending on what is needed. If you need a rectangular part, this program will help you make such a part; if you need a linear part, it will cut a linear part. This program is used not only for woodworking, but also for furniture production, metal cutting, and so on. Thanks to the high-grade algorithm that is included in the program, cutting is carried out with minimal waste.

Another one interesting program cutting is a program Astra-D. It is intended for the purpose of automated cutting of particle board. It is also used for cutting other materials, such as plastic, glass, metal and others. In addition, the Astra-D program increases efficiency and reduces the time spent when creating a cutting map. The program is designed for operating system Windows. The user will be able to master the work in this program and simply understand the menu system.

Now let's look at the program BestCut. This program facilitates tasks related to cutting chipboard, calculating the price of materials and work. With its help, you can obtain a cutting diagram for chipboard and equipment that will be used in this procedure. Also, this program will allow you to obtain accurate cutting maps for chipboard sheets into rectangular parts. An important fact is that the features that will have to be encountered in the process of processing chipboard sheets are taken into account. Work can be supported through local network, and this is also quite convenient.